Technologies

MACHINERY UTILISED

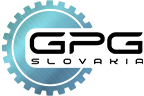

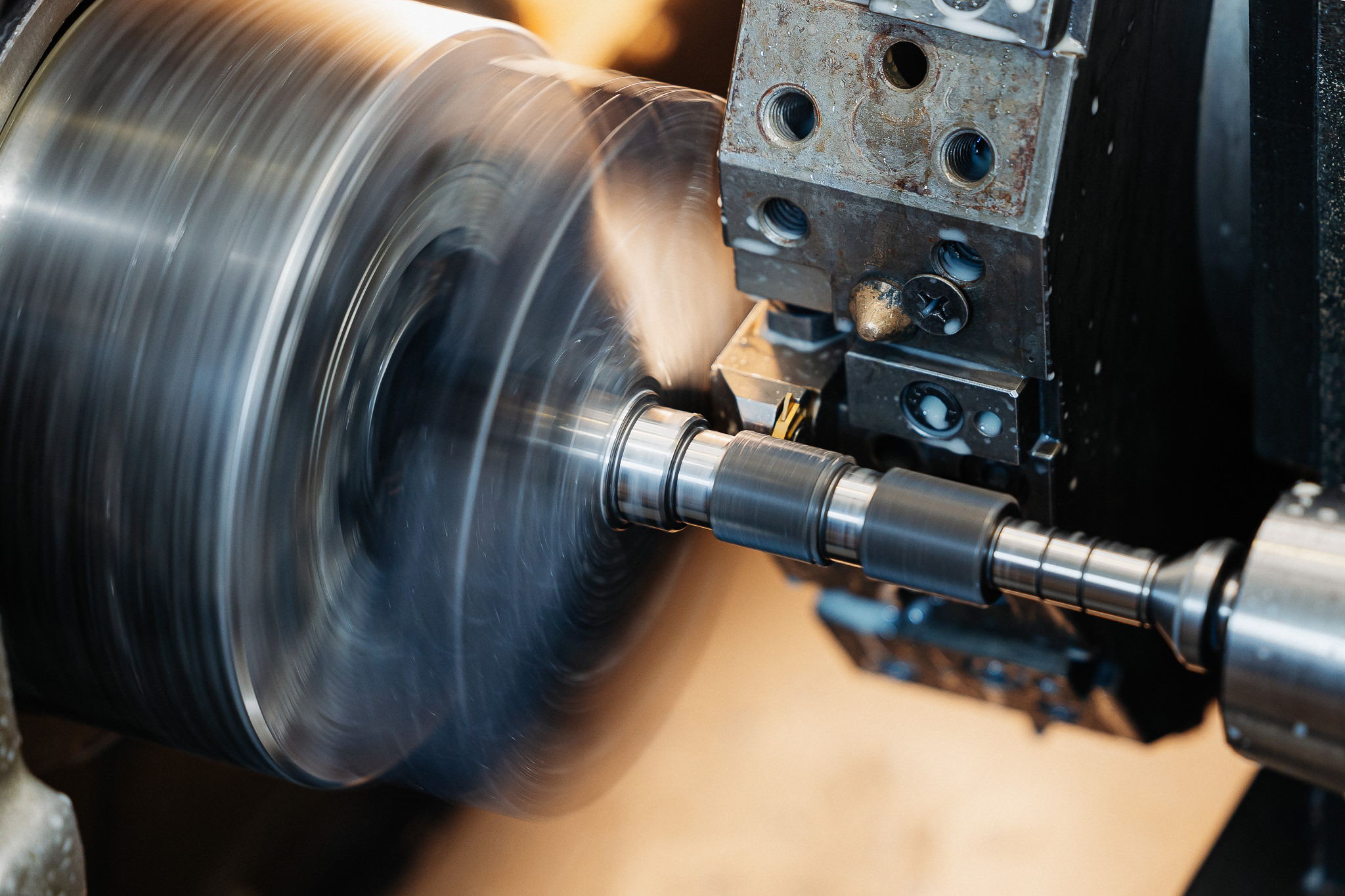

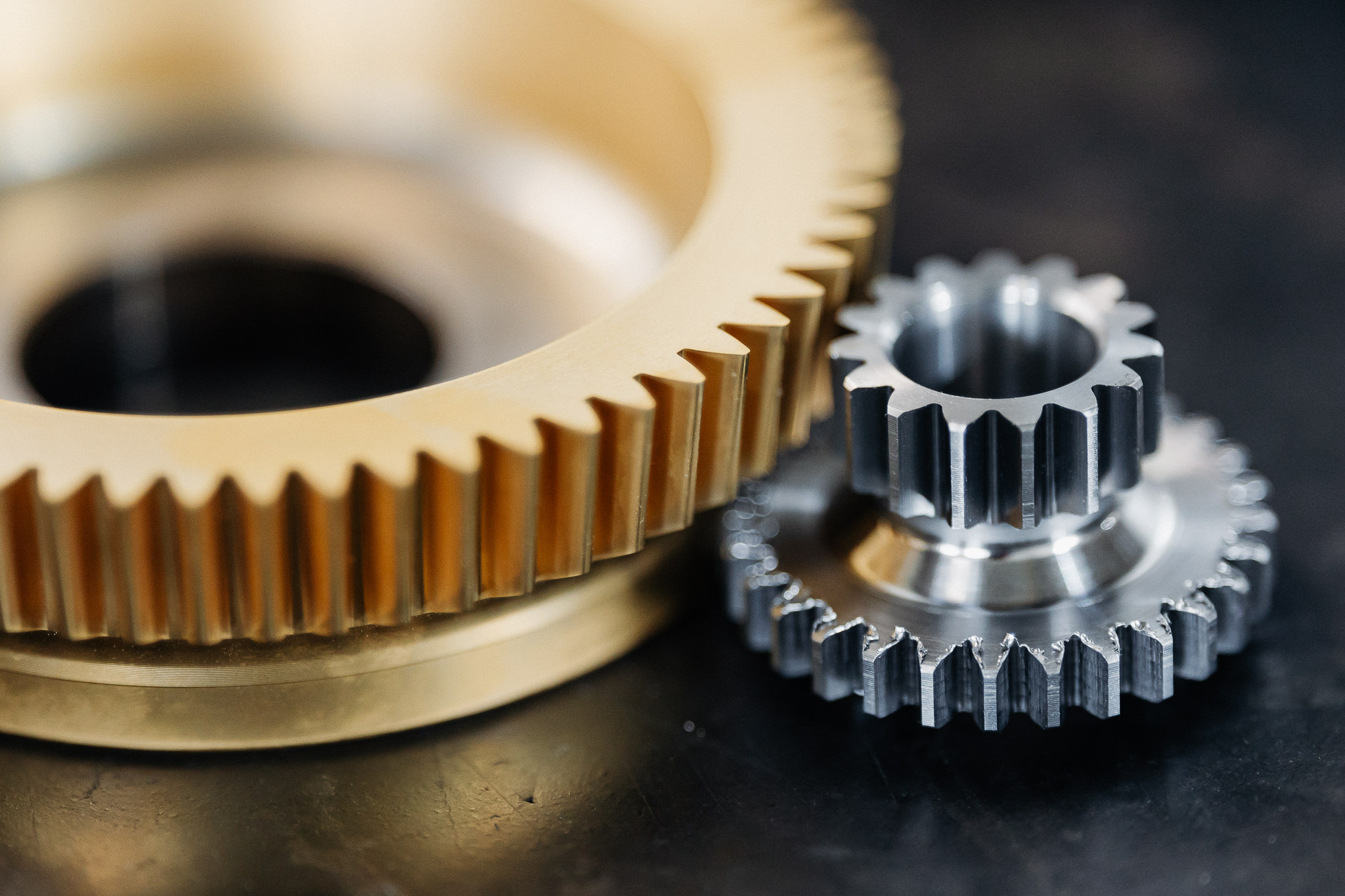

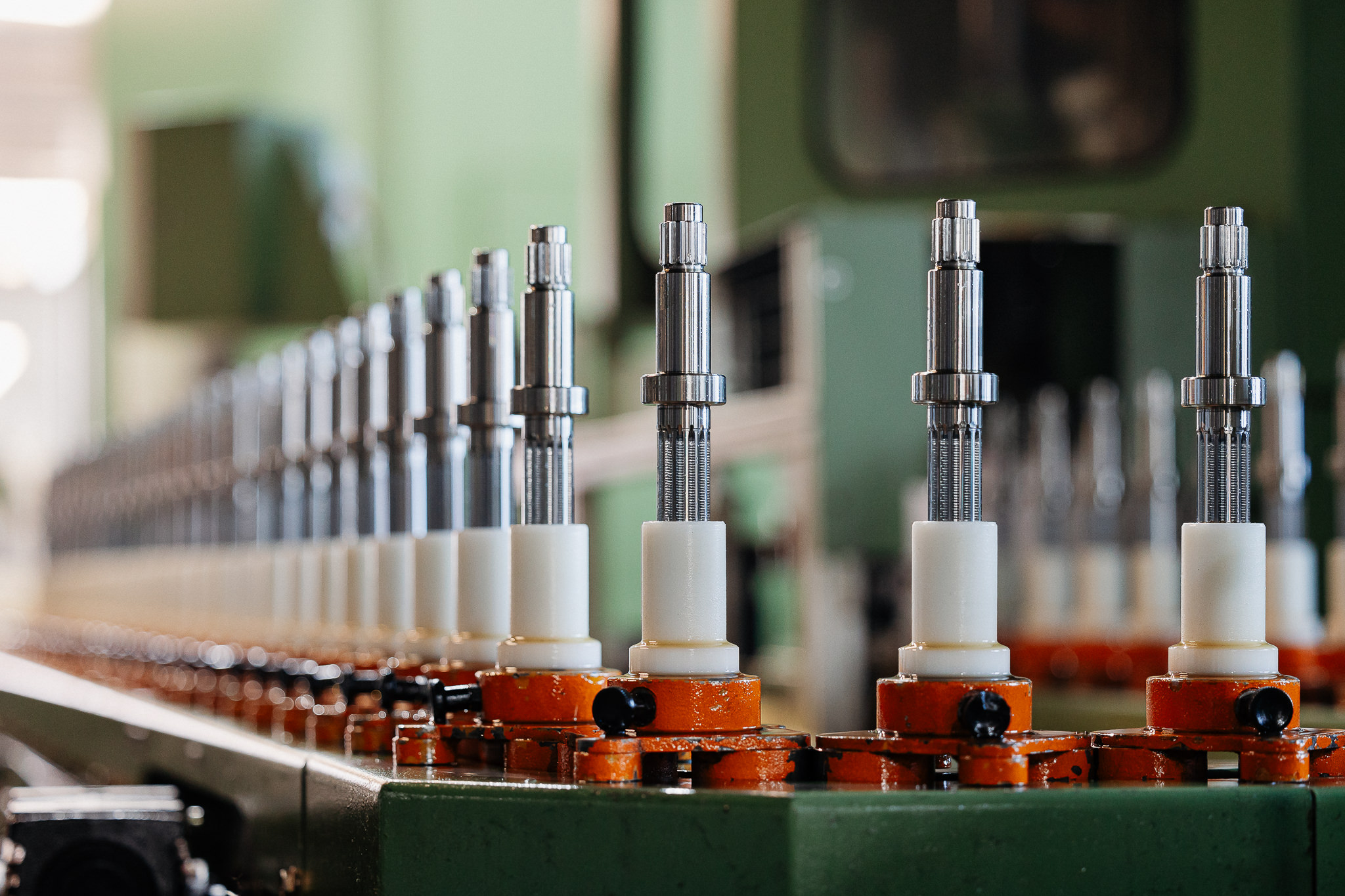

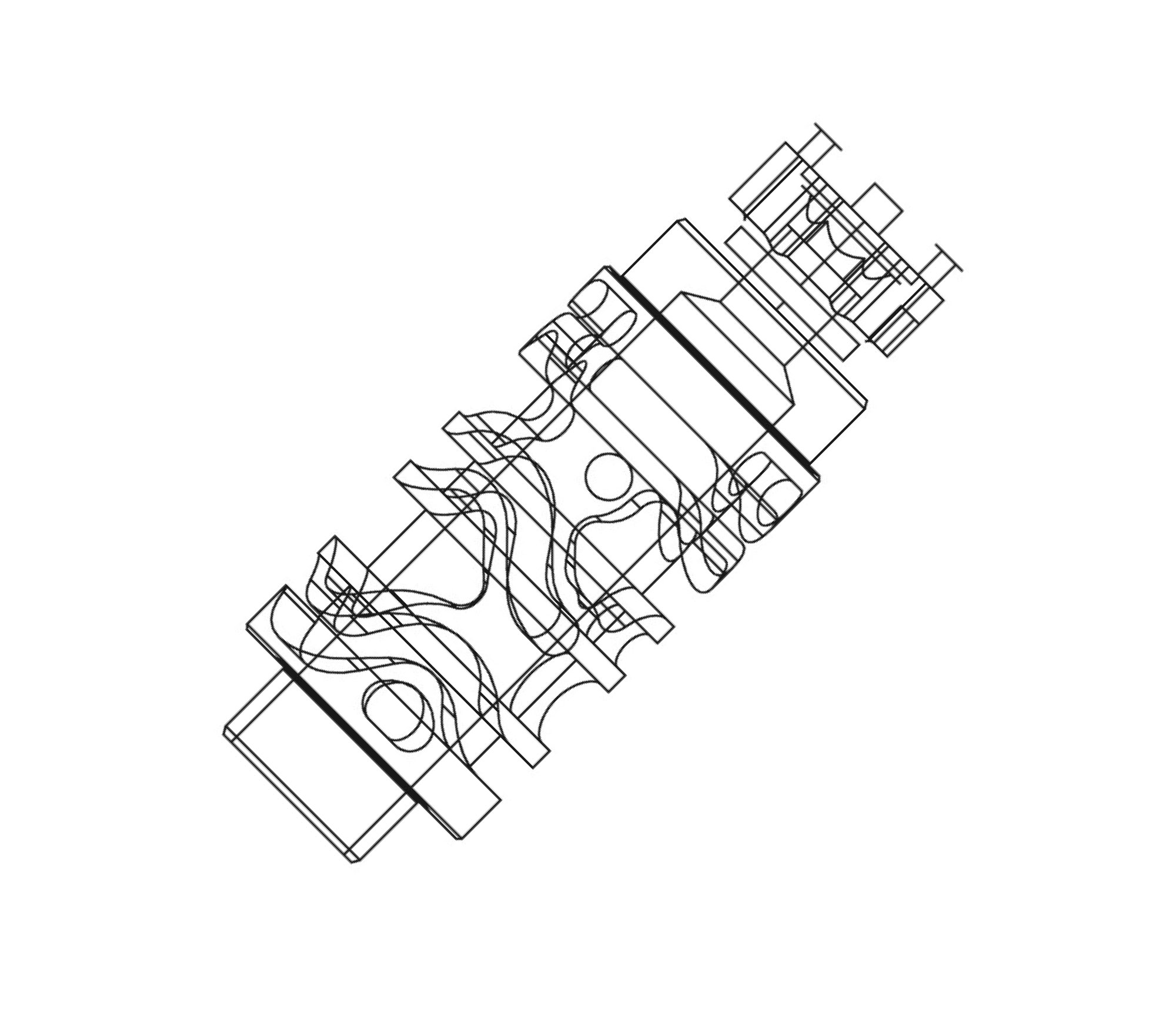

GPG SLOVAKIA performs the complete process of manufacturing from turning to grinding and eventual assembly. During production, we use the technologies of broaching, gear hobbing or gear milling, milling on CNC milling machines, deburring, cutting-edge milling, cylindrical grinding, jig grinding and gear grinding.

To increase flexibility and quality, we also provide sharpening of hobbing and gear shaping cutters. Following each sharpening, they are sent to a specialist company for coating.

PROPOSAL

realization

CNC MACHINING CENTERS:

1x PINNACLE VMC 850; 4 axes; 1000x500 (table size)

1x PINNACLE VMC 650; 3 axes; 800x500 (table size)

1x MORI SEIKI F-M1; 3 axes; 900x400 (table size)

1x BRIDGEPORT VMC 600; 3 axes; 800x400 (table size)

1x LEADWELL V-201; 3 axes; 600x350 (table size)

1x LEADWELL V30iF; 3 axes; 850x450 (table size)

1x DOOSAN DNM 5700; 4 axes; 1300x570 (table size)

1x PINNACLE VMC 650; 3 axes; 800x500 (table size)

1x MORI SEIKI F-M1; 3 axes; 900x400 (table size)

1x BRIDGEPORT VMC 600; 3 axes; 800x400 (table size)

1x LEADWELL V-201; 3 axes; 600x350 (table size)

1x LEADWELL V30iF; 3 axes; 850x450 (table size)

1x DOOSAN DNM 5700; 4 axes; 1300x570 (table size)

GEAR HOBBING MACHINES:

2x LIEBHERR LC252; 6 max 200mm

1x LIEBHERR LC152; 5 max 180mm

3x CIMA P4 AUR; 5 max 200mm

2x CIMA P3 C; 2 max 150mm

1x OFA 32A; 5 max 320mm

1x LIEBHERR LC152; 5 max 180mm

3x CIMA P4 AUR; 5 max 200mm

2x CIMA P3 C; 2 max 150mm

1x OFA 32A; 5 max 320mm

SHAPING MACHINES:

1x LORENZ SN4; 4 max

1x LORENZ LS200; 4 max

1x LORENZ LS256-CNC; 4 max

1x OHA 12A; 3 max

1x OHA 16; 4 max

1x LORENZ LS200; 4 max

1x LORENZ LS256-CNC; 4 max

1x OHA 12A; 3 max

1x OHA 16; 4 max

BROACHING MACHINES:

1x VARINELLI 35

1x SVA M7B 520 60

1x SVA M7B 520 60

SHAVING MACHINES:

2x HURTH; 5 max

GEAR GRINDING MACHINES:

2x REISHAUER RZ300E; 5 max

CYLINDRICAL GRINDERS:

1x 2UD75 500 max length 200

1x PALMARY OCD 3240 CNC

1x PALMARY OCD 3240 CNC

THREAD GRINDING MACHINES:

1x REISHAUER NRK

SURFACE GRINDERS:

1x BERNARDO 300x600

TURNING MACHINES:

2x HITACHI SEIKI TS 15 CNC

1x LEADWELL T-6 CNC

1x BERNARDO 160 NC

1x LEADWELL T-6 CNC

1x BERNARDO 160 NC

DRILLING MACHINES:

3x TOS

2x PROMA

2x PROMA

Gallery /

MACHINERY UTILISED BY GPG SLOVAKIA